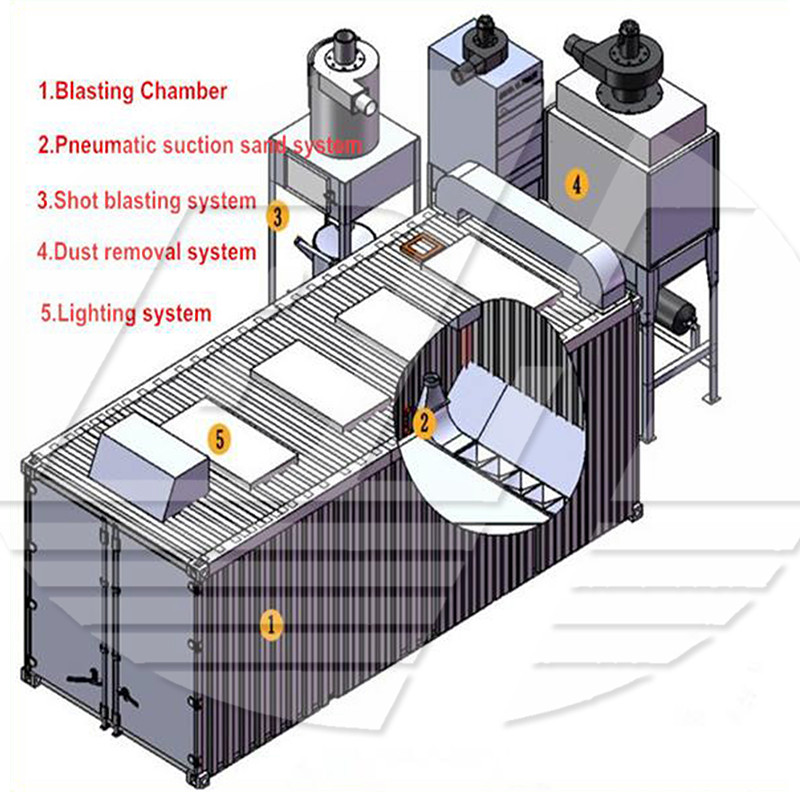

BHQ26 letoto la sandbast cabinet ka tataiso

1.Lehlabathe blast khabinete ke eng

Batho ba bang ba boetse ba bitsa mechini ea ho qhomisa lehlabathe, tanka e qhomisang lehlabathe, lehlabathe le nkehang habobebe, mechini e bulehileng ea ho qhomisa lehlabathe joalo-joalo.Mabitso a fapane, empa ha e le hantle a na le moelelo o tšoanang.E ka sebetsa e arohane, empa hangata e sebetsa ka phaposi ea ho thunya.

Sebopeho sa khabinete e phatlohang lehlabathe ——

Ha e le hantle, likarolo tsena ke tse latelang:

1).tanka e qhomisang lehlabathe:

Botenya ba poleiti ea tšepe e sebelisoang bakeng sa mefuta e fapaneng ea tanka le motso oa mochini oa sandblasting e fapane.Ha molumo o le moholo, poleiti ea tšepe e teteaneng.Sena se khethoa haholo-holo ke fektheri ea sekepe sa khatello ho latela boemo ba sebele.

Ho na le mefuta e 'meli ea valve ea lehlabathe le valve ea lehlabathe: manual kapa pneumatic.Ka letsoho, hoa hlokahala ho bula valve ea lehlabathe ka letsoho, 'me khase e buloa ka bo eona ka khase.

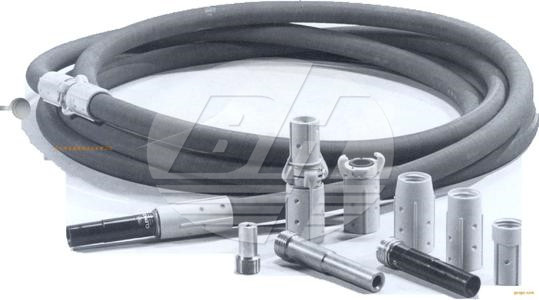

2) Peipi e qhomisang lehlabathe (e tloaelehileng ke 10m/20m)

3).Belofo ea tšireletso

Khatello ea tšebeliso ea tanka ea sandblasting hangata ke 8KG.Karolo ea valve ea polokeho Ha khatello ea khase e feta 8KG, e tla itokolla ka bo eona.E le ho sireletsa tanka ea sandblasting

4) . Sethunya sa Sandblasting: Ho ea ka thepa, e ka aroloa ka boron carbide, alloy steel, tungsten carbide, tšepe joalo-joalo.

E tšoarellang ka ho fetesisa ke boron carbide, mme bophelo ba ts'ebeletso hangata ke lihora tse 500-700.

Taba ea bobeli, bophelo ba ts'ebeletso ea tungsten carbide le tšepe ea alloy hangata ke lihora tse 300-400,

Tšepe e ka sebelisoa lihora tse 10 feela, ke batho ba fokolang ba e sebelisitseng.

Sistimi ea taolo ea elektronike le likarolo tse ling.

2.Molao-motheo oa ho sebetsa oa sandblaster e nkehang habonolo

Molao-motheo oa ts'ebetso ea mochini o qhomisang lehlabathe o fapane le mochini o thunyang.Mochini oa ho thunya o sebelisa matla a centrifugal ho thunya.Mochini oa ho qhomisa lehlabathe o tsamaisoa ke moea o hatelitsoeng mme o fafatsa li-abrasives (ka bobeli lehlabathe la tšepe le le seng la tšepe) holim'a sebaka sa mosebetsi.Ka lebaka la tšusumetso ea khatello, sekoti se ka tankeng ea lehlabathe se feta ka har'a valve ea lehlabathe le ho phatloha ha tube ho ea ho sethunya sa spray, 'me sekoti se ntšoa ka lebelo le phahameng, se fetolang thepa ea mechine ea bokaholimo ba sebaka sa mosebetsi.Ka lebaka la tšusumetso le phello ea ho itšeha ea abrasive holim'a workpiece holim'a workpiece , Ho fumana tekanyo e itseng ea bohloeki le mefuta e sa tšoaneng ea bohloeki holim'a sebaka sa mosebetsi, ho ntlafatsa thepa ea mochine oa sebaka sa mosebetsi, kahoo ntlafatsa ho hanyetsa mokhathala oa workpiece, eketsa sekhomaretsi pakeng tsa eona le ho roala, 'me le atolose ho roala The durability ea filimi e boetse e loketseng ho leveling le mokhabiso oa barbotage, ho tlosa litšila, lerata le oxide le dikarolo ka holim'a metsi, ha roughening holim'a seaplane, etsa hore. khatello e setseng holim'a substrate le ho ntlafatsa ho thatafala ha karolo e ka tlaase.

3.Main specification bakeng sa portable sand blaster

4. Ho lahleheloa ke matla a tanka ea ho thunya

1).Tlhophiso ea mohloli oa moea oa mochini oa sandblasting hangata ke 6m³/min (tšebeliso ea moea ea sethunya se le seng sa spray, haeba e le N, tlhophiso e hlokahalang ea mohloli oa moea ke N*6m³/min.

| Mofuta oa Ntho | Q0250 | Q0250A-Ⅱ | Q0250A-Ⅱ-LX | ||

| Bophahamo ba tanka (m3) | 0.5 | 0.7 | 0.82 | ||

| Khatello ea moea (Mpa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | ||

| Tekanyetso e nkiloeng (caliber=φ10)(kg/h) | 1800-2280 | 1 sethunya | 1800-2280 | 1 sethunya | 1800-2280 |

| 2 lithunya | 3600-4560 | 2 lithunya | 3600-4560 | ||

| Tšebeliso ea moea (m3/mets) | 6.1 | 1 sethunya | 6.0 | 1 sethunya | 6.0 |

| 2 lithunya | 12.0 | 2 lithunya | 12.0 | ||

| Bolelele ba peipi e phatlohileng (mm) | 7000 | 7000 (2pcs) | 7000 (2pcs) | ||

| Tsela ea ho laola | Taolo e hole | Taolo e hole | Taolo e hole | ||

| Boholo (mm) | 1036*812*1860 | 1120*900*1890 | 1086*812*2060 | ||

| Boima (kg) | 396 | 500 | 690 | ||

2).Khatello ea moea e hlokoang ke mochine oa lehlabathe ke 0.5-0.6mpa (haeba khatello e le tlase haholo, ho phatloha ha lehlabathe ho tla fokola 'me phello ea ho hloekisa e tla ameha).

3).Palo ea ho phatloha ha lehlabathe / ho thunya ka hora ea mochini oa sandblasting ke 1800-2100 kg.

4) .Letoto la tšebeliso ea sandblasting

a.Phekolo ea pele: liphekolo tsohle tsa ho phatloha pele li koaheloa, tse kang electroplating, penta, ho fafatsa, joalo-joalo, bokaholimo bo hloekile ka ho feletseng, 'me ka nako e ts'oanang bo ntlafatsa haholo ho khomarela le ho hanyetsa ha kutu ea lera le koahelang.

b.Phekolo ea pele pele e hloekisa bokaholimo ba likarolo: ho theola, masala le litšila tsa likarolo tsa tšepe tse kang li-castings, likarolo tsa stamping, likarolo tsa welding, likarolo tsa phekolo ea mocheso;ho hloekisa holim'a lihlahisoa tse se nang tšepe, ho tlosoa ha matheba a matšo holim'a likheo tsa ceramic le ho fokotseha ha pente Mohlala, joalo-joalo.

c.Ho tsosolosoa ha likarolo tsa khale: ho nchafatsa le ho hloekisa likarolo tsohle tse tsamaeang tse kang likoloi, lithuthuthu, lisebelisoa tsa electromechanical, joalo-joalo Ka nako e ts'oanang ho felisa khatello ea mokhathala le ho lelefatsa bophelo ba tšebeletso.

d.Ho qeta ho sebetsa ka holim'a mosebetsi oa ho sebetsa: lihlahisoa tsohle tsa tšepe le lihlahisoa tse seng tsa tšepe (polasetiki, kristale, khalase, joalo-joalo) li tlosoa, 'me phekolo ea moholi oa argon e etsa hore sehlahisoa se ntlafatsoe.

e.Phekolo ea hlobo: kalafo ea moholi o bobebe oa Argon oa bokaholimo ba hlobo, tlhahiso ea litšoantšo, le ho hloekisa hlobo, eseng ho senya bokaholimo ba hlobo, ho netefatsa ho nepahala ha hlobo.

f.Phekolo ea Burr: Likarolo tse entsoeng ka mochini li tlosoa ka li-burrs tse nyane, 'me likarolo tsa polasetiki tsa likarolo tsa ente lia tlosoa.

g.Ho tsosolosoa ha lihlahisoa tse sa rateheng: ho tlosoa ha sehlahisoa se sa rateheng, ho tlosoa ha mebala e sa rateheng holim'a metsi le ho tlosoa ha khatiso.

h.Ho matlafatsa: eketsa boima ba bokaholimo ba likarolo tsa tšepe le ho felisa khatello ea maikutlo, joalo ka kalafo ea holim'a mahare a sefofane, liliba, lisebelisoa tsa machining le libetsa.

ke.Etching le anti-skid processing: etching pattern, text and anti-skid treatment on the surface of metal products and non-metal products, such as: marble, anti-skid handles, litiiso, stele lettering, joalo-joalo.

j.Kalafo ea liaparo tsa Denim: Seaparo sa denim se matte, bosoeu le setepisi sa katse se fihletsoe.

5. Melemo ea khabinete ea sandblast:

1).Likarolo tsa tšepe tsa mochini oa sandblasting ha e le hantle ha li senyehe, 'me ho nepahala ha dimensional ho ke ke ha fetoha;

2).Bokaholimo ba karolo ha bo silafatsoe, 'me setlolo se ke ke sa sebetsana le lik'hemik'hale ka thepa ea karolo;

3).Mochini oa lehlabathe o ka sebetsana le likarolo tse sa fumaneheng tse kang li-grooves le concave, 'me boholo bo sa tšoaneng ba li-abrasives bo ka khethoa bakeng sa tšebeliso;

4).Litsenyehelo tsa ts'ebetso li fokotsehile haholo, haholo-holo li bonahatsoa ntlafatsong ea katleho ea mosebetsi oa mochine oa sandblasting, o ka finyellang litlhoko tse sa tšoaneng tsa ho qeta holim'a metsi;

5).Tšebeliso e tlaase ea matla le litšenyehelo tse tlaase;

6).Mochini oa lehlabathe ha o silafatse tikoloho, o felisa litšenyehelo tsa phekolo ea tikoloho;