BHQ26 letoto la lihlooho tse lehlabathe qhomisa setshelo ka theko moruo

setshelo sa ho qhomisa lehlabathe

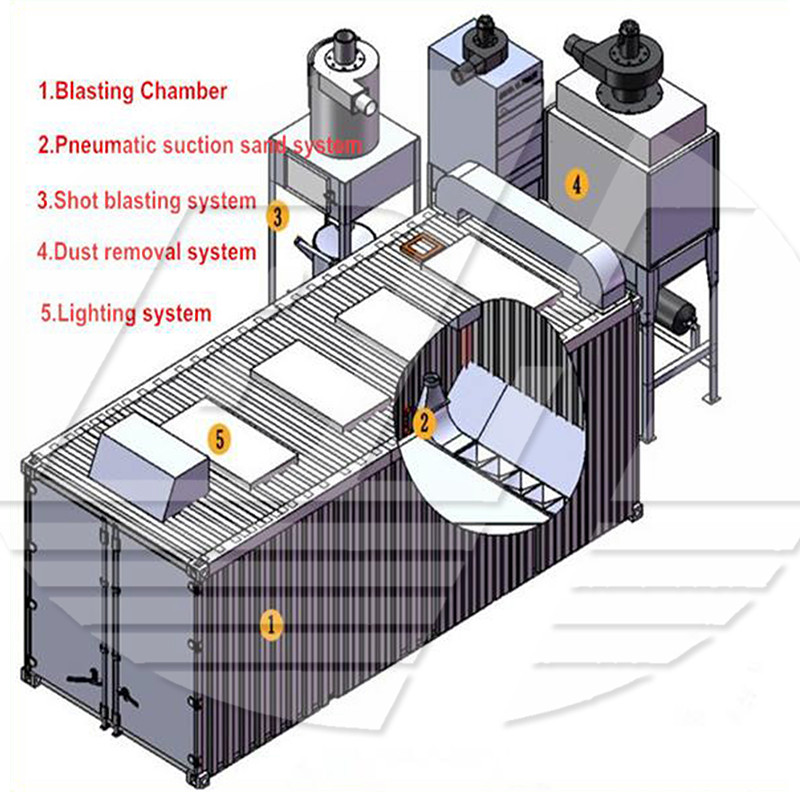

Haholo-holo e entsoe ka kopano ea sethunya sa sethunya, kamore ea ho thunya, sistimi ea lipalangoang tsa trolley, sistimi ea ho tlosa lerōle, sistimi ea taolo ea motlakase le likarolo tse ling.

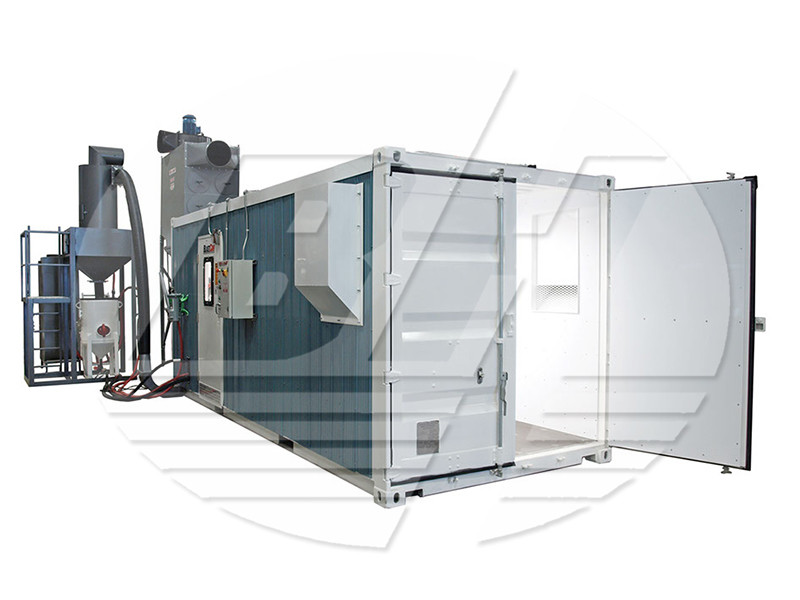

1 Kamore ea ho hlapela

Khetla ea kamore ea ho hloekisa e entsoe ka 'mala oa tšepe ea rock wool sandwich composite board le sebopeho sa tšepe se nang le khutlonnetsepa, e leng sebaka sa ts'ebetso se matla, se tiisitsoeng le se sephara bakeng sa ho phatloha ha mochini oa mosebetsi.Kamore ea ho hloekisa e entsoe ka mabota a ka ho le letšehali le ka ho le letona, lebota le ka morao, top plate, rabara guard plate le heke.Kamore ea ho thunya e na le mabone a tšepe a halide (a sirelelitsoeng ka mesh ea tšepe e sa hloekang).Bokahare ba kamore bo sirelelitsoe ke balebeli ba rabara e tšoeu, 'me balebeli bohle ba kentsoe liboutu tsa lifaha.Monyako oa kamore ea ho thunya o sebelisa folio ea mofuta oa setshelo.

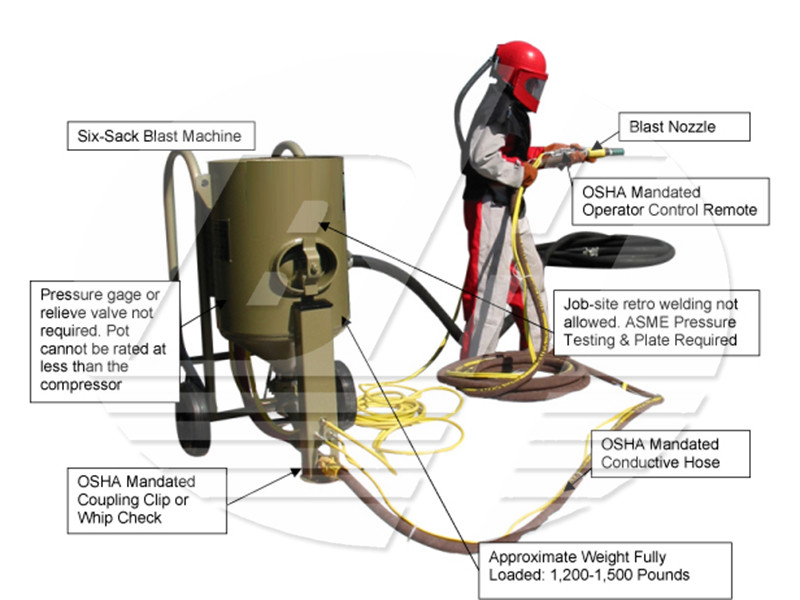

2 Kopano ea sethunya se thunyang

Kopano ea sethunya sa sethunya se entsoe ka tanka, nozzle, nozzle, element ea moea, joalo-joalo. Ke ts'ebetso e kholo e tsoelang pele ea sethunya se habeli.Nozzle e entsoe ka boron carbide mme e tšoarella nako e telele.Nozzle e entsoe ka ultra-wearable high-pressure rubber tube Har'a bona, tlhahiso ea litanka e na le qualification ea ho etsa likepe tsa khatello.

3 Sistimi ea tlhoekiso ea phallo ea lipilisi

Sesebelisoa sa tlhoekiso ea ho potoloha ha pellet se kenyelletsa sistimi ea ho potoloha le sistimi ea tlhoekiso ea pellet, e entsoeng ka sekoahelo sa screw, lifti ea libakete, searolahi sa lehlabathe la pellet, valve ea heke ea phepelo ea pellet, le phala ea phano ea pellet.

Screw conveyor:

The screw conveyor e entsoe ka casing, screw shaft, bearing e nang le setulo, mochine oa ho khanna, joalo-joalo. Ke karolo ea serialized ea k'hamphani ea rona, e nang le mefuta-futa e phahameng, e feto-fetohang haholo, le ts'ebetso e tsitsitseng le e ka tšeptjoang.

Karolo ena e na le boikarabelo ba ho fetisetsa motsoako oa lehlabathe le thunngoeng holim'a lifti.The screw conveyor e botlaaseng ba kamore ea ho hloekisa e phatlohang, 'me li-screw blades li cheselitsoe ho shaft ea koloi.Ha e sebetsa, mochini o tsamaisang thepa o khanna screw conveyor ho potoloha ka cycloid reducer ho tsamaisa li-pellets ho ea boema-kepe ba ho ntša metsi, ebe boema-kepe ba ho tsoa bo fetisetsa li-pellets tse hasantsoeng le motsoako oa lerole tlase ho lifti.

Likarolo tse peli tsa "screw conveyor" li sirelelitsoe ka tiiso ea mekhahlelo e meraro, sekoaelo sa labyrinth se kenyelelitsoe ka har'a poleiti ea ho qetela, tiiso ea oli e sebelisoa bakeng sa tšireletso bohareng, 'me ho beleha ho arohanngoa le poleiti ea ho qetela ka ntle ho qetellong. poleiti.Hang ha li-pellets le lerōle li ntšoa, li tla oa ho tloha lekhalo pakeng tsa poleiti ea ho qetela le ho bea 'me li ke ke tsa kena ho beng.

Bucket lifti:

Lifilimi tsa libakete li entsoe ka cycloidal pin wheel reducer speed, li-roller tse ka holimo le tse tlase, lebanta la conveyor, hopper, moqomo o koetsoeng le sesebelisoa sa tsitsipano, joalo-joalo, 'me matla a khoheli a centrifugal a sebelisetsoa ho koala.

Ha e sebetsa, hopper e tsitsitseng lebanta la conveyor e senya li-pellets ka tlase ebe e romela li-pellets holimo, ebe e oela ka matla a khoheli a centrifugal.Ho amohela lebanta le khethehileng la phetisetso ea terata ea polyester, matla a phahameng le ts'ebetso e phahameng ea ts'ebetso.

Pulley e nka sebopeho sa squirrel-cage se nang le sekhahla se senyenyane bohareng, 'me puo e' ngoe le e 'ngoe e sebetsanoa ka chamfering.Ha e ntlafatse feela likhohlano pakeng tsa tepi e phahamisang le pulley, e qoba ts'ebetso e thellang ea pulley e khanyang ea khale le pulley ho lebanta, empa hape e fokotsa boikaketsi ba lebanta le phahamisang le ho lelefatsa bophelo ba tšebeletso;ka nako e ts'oanang, e qoba ho kenngoa ha bomo e hasaneng Pakeng tsa pulley le lebanta le ama phetiso.

Ho na le moeli oa 10% bakeng sa lifti.Hobane hoist e oela ka matla a khoheli a centrifugal, nako le nako ha e oela, ho tla lula ho e-na le karolo ea thepa e oelang ka har'a sekoti, kahoo hoa hlokahala ho eketsa palo ea ho phahamisa ka mokhoa o nepahetseng.

Searohanyi sa Pellet:

Mochini ona o sebelisa sephahanyi se tsoetseng pele ka ho fetesisa se tsoetseng pele sa likharetene tse felletseng lefatšeng ka bophara, 'me katleho ea sona ea karohano ke ≥99.5%.Karohano ena ke mofuta oa morao-rao oa karohano ea k'hamphani ea rona.Karohano ke e 'ngoe ea likarolo tsa bohlokoa tsa thepa ena.Boholo ba moralo oa sebaka sa karohano bo ama ka ho toba phello ea karohano ea karohano.Haeba phello ea karohano e se e ntle, e tla potlakisa ho roala ha lehare la ho phatloha.

4 Sistimi e tsamaisang trolley

Lipalangoang tsa likoloi tse bataletseng li amoheloa;ho jara mojaro ho hlophisitsoe ho latela maemo a nnete a moreki.Ho ea ka boemo ba workpiece, sutumetsa koloi e bataletseng ka phaposing ea ho hloekisa ho fumana thunya e pening.Karolo e ka pele ea lebili e ka ba le scraper ea polyurethane ho hlakola li-projectiles tse kaholimo ho seporo.

5 Sistimi ea ho tlosa lerōle

Sistimi ea ho tlosa lerōle e kenyelletsa pokello ea lerōle ea filthara ea cartridge, fan, motor, pipeline, chimney, joalo-joalo.

Automatic pulse back-flushing, valve e tlosang lerōle e nka taolo ea moea, 'me moqomo o bokellang lerōle o nang le rolara o hlophisoa ka tlas'a molora, ho qoba ts'ebetso ea lerōle ea bobeli e bakoang ke ho phuphusela ka morao.

Sefahla sa lerole se ka ntšoa habonolo bakeng sa ho hloekisoa le ho sebelisoa hape.

6 Sistimi ea motlakase

Shot blaster, monyako oa tlhokomelo, molaoli oa projectile le tsamaiso ea potoloho ea projectile kaofela li na le lisebelisoa tsa motlakase le mokhoa oa ho itšireletsa ho netefatsa ts'ebetso e tšepahalang ea lisebelisoa le polokeho ea basebetsi.Mochini o phetlelang lerōle ka morao o sebelisa taolo e iketsang ea ho otla ha pelo.